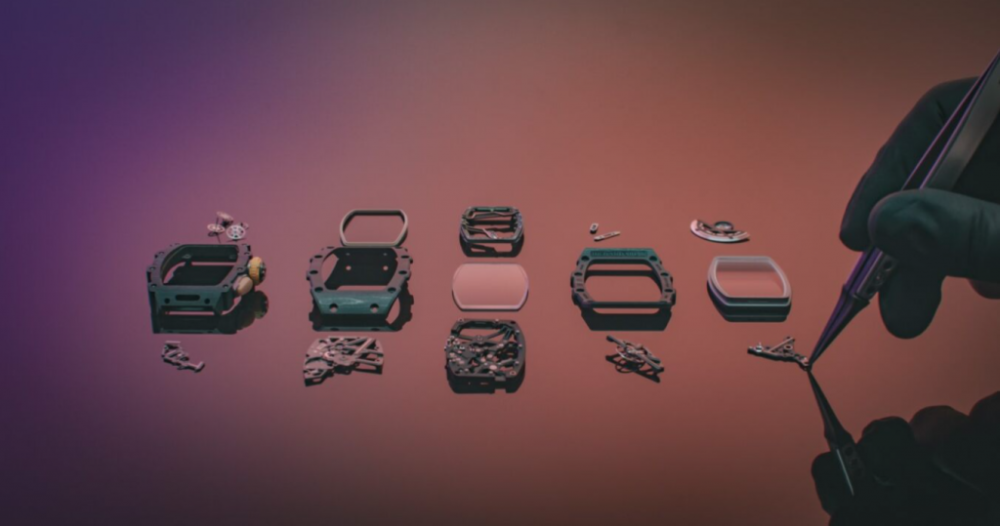

Richard Mille uses a combination of traditional know-how and futuristic vision to create watches such as the RM 07-04 that refuse to compromise on quality or technicality

A Richard Mille watch is far more than a means to keep time. As the manufacture itself explains, a Richard Mille watch is where progress meets tradition and mechanical engineering blends with craftsmanship. And the place where it all comes together is Les Breuleux, Switzerland. It is here that some of the world’s most skilled and knowledgeable watchmakers painstakingly develop, design, assemble and perfect what have come to be known as “racing machines on the wrist”.

At the heart of the operations in Les Breuleux is the Montres Valgines building, part of a family-owned company that Richard Mille joined forces with in 1999 and whose history dates back to 1900. The assembly of movements, inspection of barrels, and fitting of dials, hands and straps all take place here.

The Montres Valgines facility is complemented by two state-of-the-art buildings. Designed by the Chavanne architecture agency and opened in 2013, ProArt I occupies 32,000 sq ft. Richard Mille cases, as well as a number of movement components, including baseplates, bridges, screws and some wheels, are manufactured at this site. ProArt II was added in 2018, resulting in another 27,000 sq ft and the ability to incorporate new trades in-house such as those related to the purchase of diamonds or decoration including the creation of a gem-setting workshop. This impressive building is also home to the brand’s technical offices, namely case and movement engineers, the R&D teams, and artistic and development direction.

Both ProArt I and ProArt II operate in the machining of watch and movement components, with a specialisation in manufacturing components from composite and technical materials such as Carbon TPT, Quartz TPT, Graph TPT, titanium and ceramic, as well as noble metals such as gold and platinum.

One example of the kind of innovative timepieces being developed and crafted at Richard Mille’s workshops in Les Breuleux is the RM 07-04 Automatic Sport, which is as much about aesthetics as it is about technicity. The brand’s first women’s sport watch required three years of development due to many challenges: developing a new, very compact and skeletonised in-house automatic movement, guaranteeing high shock resistance and integrating the exterior perfectly into the movement while leaving its workings visible, to name a few.

The CRMA8 calibre is a new in-house automatic movement with hours, minutes and a function selector. It underwent a series of rigorous tests to confirm its resistance to 5000 g’s of acceleration, a major feat for the most compact of all the calibres developed by Richard Mille. The hand at 5 o’clock indicates the chosen function on a flange in grade 5 titanium. A part as finely worked as those of the movement, this crucial element in the architectural aesthetics of the piece brings balance to the whole and contributes to the symbiosis between movement and decoration. Depending on the version, the case is crafted of Quartz TPT or Carbon TPT.

Lightweight – at 36 grams including its Velcro strap – the RM 07-04 Automatic Sport collection offers athletes the freedom to be at their very best in their disciplines while displaying the expertise of the watchmaker for whom there is not the slightest margin for error.

Also see: Year of the Dragon fashion accessories